Understanding the Role and Applications of RV Reducer in Industrial Automation

RV reducers, also known as worm gear reducers, are a critical component in the field of industrial automation. They are designed to reduce the speed and increase the torque of a motor, which is essential for many mechanical systems. This article delves into the intricacies of RV reducers, their applications, and why they are indispensable in modern industrial processes.

What is an RV Reducer?

An RV reducer is a type of speed reducer that uses a worm gear set to achieve a high reduction ratio. The worm, which is a threaded screw, meshes with the worm wheel, which is a toothed wheel. This interaction allows for a significant decrease in speed while increasing the torque output. The compact design and high efficiency of RV reducers make them a popular choice for various applications where precise control of speed and torque is required.

Key Features of RV Reducers

RV reducers are known for their compact size, high efficiency, and long service life. They are also appreciated for their low noise operation and high precision. These features make RV reducers ideal for applications where space is limited, and high torque is needed at low speeds. Some of the key features include:

- High reduction ratios, which can range from 5:1 to 100:1 or even higher depending on the model.

- Compact design, which saves space and simplifies integration into existing systems.

- High efficiency, often above 90%, which reduces energy consumption and increases the overall efficiency of the system.

- Long service life, due to the robust construction and precision engineering of the components.

- Low noise operation, which is beneficial in environments where noise pollution is a concern.

Applications of RV Reducers

The versatility of RV reducers makes them suitable for a wide range of applications across various industries. Some of the common applications include:

- Conveyor systems, where precise control of belt speed is necessary for efficient material handling.

- Machine tools, such as lathes and milling machines, where high torque is required for cutting and shaping materials.

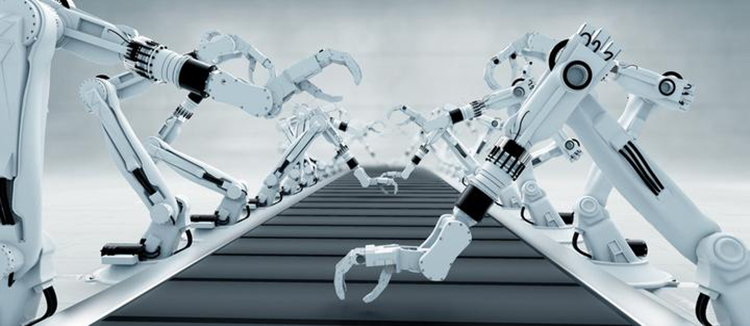

- Automated assembly lines, where consistent and controlled motion is critical for the assembly of products.

- Agricultural machinery, where the reduction of speed and increase of torque are needed for tasks like plowing and harvesting.

- Elevators and escalators, where precise speed control is essential for safety and comfort.

Why Choose an RV Reducer?

Choosing an RV reducer for your industrial application offers several advantages:

- Reliability: RV reducers are known for their reliability and durability, which reduces downtime and maintenance costs.

- Efficiency: The high efficiency of RV reducers contributes to energy savings and lower operational costs.

- Precision: The precision of speed and torque control is crucial for applications that require exact movements and forces.

- Versatility: The wide range of reduction ratios and sizes available makes RV reducers suitable for a variety of applications.

Conclusion

RV reducers play a pivotal role in industrial automation by providing a reliable and efficient means of speed reduction and torque increase. Their compact design, high efficiency, and precision make them an ideal choice for a multitude of applications. Whether you are involved in the design of new machinery or looking to upgrade existing systems, considering the integration of RV reducers can lead to significant improvements in performance and efficiency.