Unlocking Industrial Automation with Multi Axis Robotic Arm: A Comprehensive Guide

As the world of manufacturing and automation continues to evolve, the Multi Axis Robotic Arm stands as a testament to the progress and innovation in industrial technology. These sophisticated machines are designed to perform a wide range of tasks with precision and efficiency, revolutionizing the way we approach production and assembly lines. In this comprehensive guide, we will delve into the intricacies of Multi Axis Robotic Arms, exploring their capabilities, applications, and the impact they have on modern industries.

The Multi Axis Robotic Arm, as the name suggests, is a type of robotic arm that operates on multiple axes, allowing for a high degree of flexibility and movement. These axes are the directions in which the arm can move: typically, this includes linear movements along the X, Y, and Z axes, as well as rotational movements around these axes. This multi-axis capability is what sets them apart from simpler, single-axis robots, enabling them to reach complex geometries and perform intricate tasks.

One of the primary advantages of Multi Axis Robotic Arms is their versatility. They can be programmed to perform a variety of tasks, from simple pick-and-place operations to more complex assembly and machining processes. This adaptability makes them ideal for industries that require rapid changes in production lines or the ability to handle a diverse range of products.

Another key benefit of Multi Axis Robotic Arms is their precision. With advanced sensors and control systems, these arms can execute tasks with a high degree of accuracy, reducing the margin for human error and improving overall product quality. This precision is particularly important in industries such as electronics manufacturing, where small components need to be assembled with exacting specifications.

Efficiency is also a hallmark of Multi Axis Robotic Arms. By automating repetitive tasks, these arms can significantly increase production speeds and reduce downtime. This not only leads to cost savings but also allows companies to remain competitive in a global market where time-to-market is crucial.

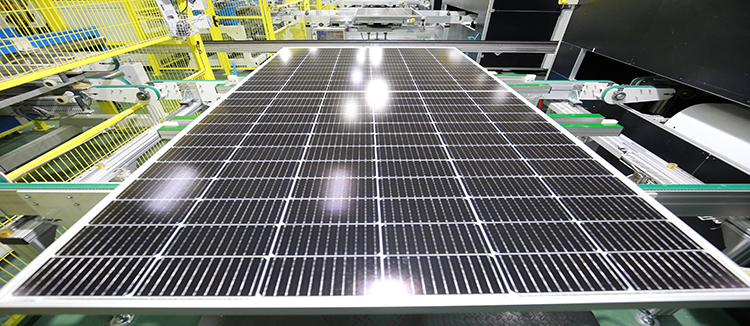

The applications of Multi Axis Robotic Arms are vast and varied. In the automotive industry, they are used for welding, painting, and assembly tasks. In electronics manufacturing, they are employed for component placement and PCB assembly. In the food and beverage industry, they can be found in packaging and palletizing operations. The medical sector also utilizes these arms for precise surgical procedures and pharmaceutical handling.

As technology advances, the capabilities of Multi Axis Robotic Arms continue to expand. With the integration of artificial intelligence and machine learning, these arms are becoming more autonomous, able to learn from their environment and adapt their actions accordingly. This development is opening up new possibilities for automation, pushing the boundaries of what is possible in industrial settings.

Despite their many benefits, the implementation of Multi Axis Robotic Arms does come with challenges. The initial investment can be high, and there is a need for skilled personnel to program and maintain these complex systems. However, as the technology matures and becomes more accessible, these barriers are gradually being overcome.

In conclusion, the Multi Axis Robotic Arm is a powerful tool in the realm of industrial automation. Its ability to perform tasks with precision, efficiency, and versatility makes it an invaluable asset to a wide range of industries. As technology continues to progress, we can expect to see even more innovative applications of these arms, further transforming the way we approach manufacturing and production.