The Revolutionary Role of Linear Motor Technology in Modern Applications

Linear motors have been a game-changer in the field of motion control, offering a range of advantages that traditional rotary motors cannot match. This article delves into the revolutionary role of linear motor technology and its impact on various industries, from transportation to manufacturing.

A linear motor is an actuator that produces motion in a straight line without the use of any mechanical linkages or conversion elements. It operates on the same basic principles as a rotary motor, but instead of producing rotational motion, it generates linear motion. This direct conversion of electrical energy to linear motion makes linear motors highly efficient and responsive.

One of the key benefits of linear motors is their high speed and acceleration capabilities. Due to the absence of mechanical linkages, there is less inertia and friction, allowing for rapid starts and stops. This characteristic makes linear motors ideal for applications requiring quick and precise movements, such as in high-speed trains and maglev systems.

Another advantage of linear motors is their ability to provide precise positioning. The direct drive nature of linear motors eliminates the need for additional positioning mechanisms, such as gears or belts, which can introduce errors. This precision is crucial in applications like semiconductor manufacturing, where the accuracy of component placement can significantly impact the performance of the final product.

The absence of mechanical wear in linear motors also contributes to their long-term reliability and reduced maintenance requirements. This is particularly beneficial in harsh environments or in applications where access for maintenance is difficult or costly, such as in offshore drilling platforms or space applications.

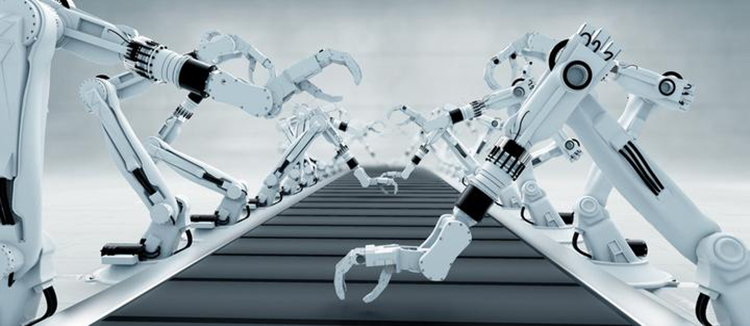

Linear motors are also known for their high force-to-weight ratio. They can generate significant force with a compact design, making them suitable for applications where space is at a premium, such as in robotics and automation. This compactness, combined with their high force output, allows for the development of more efficient and powerful machines.

In the field of transportation, linear motors have been instrumental in the development of maglev trains. These trains use linear motors for both propulsion and levitation, eliminating the need for wheels and reducing friction, which in turn allows for higher speeds and smoother rides.

Linear motors are also finding their way into the medical industry, particularly in advanced surgical equipment. Their precision and control capabilities are invaluable in procedures that require delicate manipulation, such as in microsurgery or robotic-assisted surgery.

The environmental benefits of linear motors should not be overlooked. Their energy efficiency and reduced maintenance requirements contribute to lower energy consumption and less waste, aligning with the global push towards sustainability and green technologies.

As technology continues to advance, the applications for linear motors are expanding. They are being integrated into more and more systems, from simple conveyor belts to complex manufacturing lines, and from everyday household appliances to cutting-edge scientific instruments.

The future of linear motor technology looks promising, with ongoing research and development aimed at improving efficiency, reducing costs, and expanding the range of applications. As these advancements are made, linear motors are poised to play an even more significant role in shaping the future of motion control and automation.