Exploring the Versatility and Impact of Industrial Robots in Modern Manufacturing

Industrial robots have become an integral part of the modern manufacturing landscape, revolutionizing the way goods are produced and assembled. These sophisticated machines are designed to perform tasks that are repetitive, dangerous, or require high precision, thereby enhancing productivity and efficiency in the workplace. In this article, we will delve into the versatility of industrial robots, their impact on the industry, and the future they are shaping.

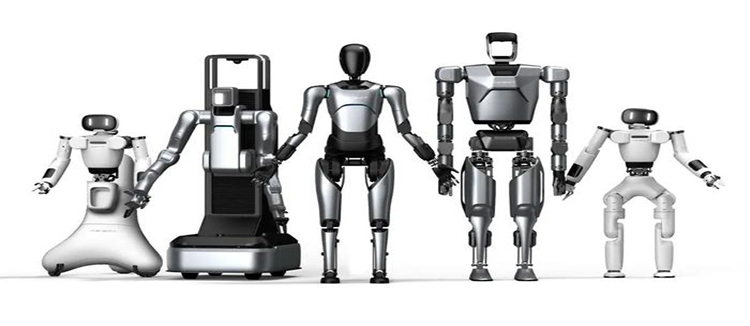

The term "industrial robot" refers to programmable, multifunctional manipulators designed to move materials, parts, tools, or specialized devices through variable programmed motions for the performance of a variety of tasks. These robots are not just limited to the automotive industry; they are now prevalent in sectors such as electronics, aerospace, food and beverage, and pharmaceuticals.

One of the key advantages of industrial robots is their ability to work tirelessly without the need for breaks, significantly reducing downtime and increasing output. They can be programmed to perform complex tasks with high precision, which is crucial in industries where quality control is paramount. For instance, in the electronics industry, industrial robots are used for tasks such as soldering, assembling small components, and testing finished products.

The impact of industrial robots on the workforce is another significant aspect to consider. While there are concerns about job displacement, the reality is that these robots often take over tasks that are monotonous or hazardous, allowing human workers to focus on more complex and creative tasks. This shift not only improves worker safety but also opens up new opportunities for skill development and job growth in areas such as robotics programming, maintenance, and system integration.

Another area where industrial robots excel is in their adaptability. With advancements in artificial intelligence and machine learning, these robots are becoming more intelligent and capable of learning from their environment. This adaptability allows them to handle a wider range of tasks and to work in harmony with human workers, creating a more flexible and responsive manufacturing process.

Sustainability is also a key focus in the era of industrial robots. By optimizing production processes, these robots can help reduce waste and energy consumption. For example, in the automotive industry, industrial robots can assemble vehicles with fewer parts and less material, leading to lighter and more fuel-efficient cars. This not only benefits the environment but also aligns with the growing consumer demand for eco-friendly products.

Looking to the future, the integration of industrial robots with the Internet of Things (IoT) is set to further transform manufacturing. IoT-enabled industrial robots can collect and analyze data in real-time, allowing for predictive maintenance and more efficient resource allocation. This connectivity also enables remote monitoring and control, which can be particularly beneficial for companies with global operations.

In conclusion, industrial robots are not just tools for automation; they are catalysts for innovation and efficiency in the manufacturing sector. Their versatility, precision, and adaptability are reshaping the way we think about production, and their impact is felt across a multitude of industries. As technology continues to advance, the role of industrial robots in the future of manufacturing is set to expand, promising even greater possibilities for innovation and growth.