Unlocking the Potential of Industrial Robot Technology: Revolutionizing Manufacturing and Automation

The advent of the Industrial robot has been a game-changer in the world of manufacturing and automation. These sophisticated machines have the ability to perform tasks that were once the exclusive domain of human labor, thereby enhancing efficiency, precision, and safety in the workplace. In this article, we will delve into the world of Industrial robots, exploring their capabilities, applications, and the impact they have on the future of industry.

Industrial robots are programmable, multifunctional manipulators designed to move materials, parts, tools, or specialized devices through variable programmed motions for the performance of a variety of tasks. They are the backbone of modern automation, providing a level of precision and consistency that is unmatched by human workers. The use of Industrial robots has grown exponentially in recent years, driven by advancements in technology, the need for increased productivity, and the desire to reduce human error.

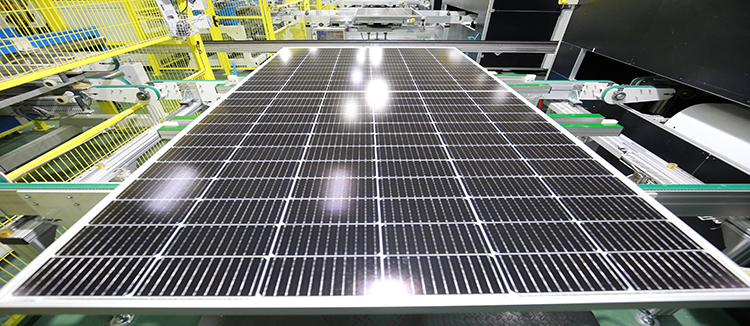

One of the primary applications of Industrial robots is in assembly lines. These robots can be programmed to perform repetitive tasks with high accuracy and speed, making them ideal for tasks such as welding, painting, and assembling complex components. The use of Industrial robots in assembly lines has not only increased the speed of production but also improved the quality of the final product by reducing the margin for human error.

Another significant application of Industrial robots is in material handling. These robots can move heavy loads with ease, reducing the risk of injury to human workers and increasing the efficiency of material movement within a facility. Industrial robots can be programmed to follow specific paths, making them ideal for tasks such as palletizing, de-palletizing, and moving materials between different stages of production.

The flexibility of Industrial robots is another key advantage. They can be reprogrammed to perform different tasks as needed, making them a versatile tool in the manufacturing process. This adaptability allows companies to respond quickly to changes in demand or to incorporate new products into their production lines without the need for significant capital investment in new equipment.

Industrial robots also play a crucial role in improving workplace safety. By taking over tasks that are dangerous or physically demanding, Industrial robots reduce the risk of injury to human workers. This is particularly important in industries such as automotive manufacturing, where tasks such as spot welding or material handling can be hazardous.

The integration of Industrial robots into the manufacturing process also has significant implications for the workforce. While the use of Industrial robots can lead to a reduction in the number of jobs that require manual labor, it also creates new opportunities for workers with the skills needed to program, maintain, and repair these sophisticated machines. As a result, there is a growing demand for workers with expertise in robotics and automation, providing new career paths for those who are willing to adapt and learn new skills.

Looking to the future, the development of more advanced Industrial robots is likely to continue at a rapid pace. Advances in artificial intelligence and machine learning are enabling Industrial robots to become even more sophisticated, capable of performing tasks that were once thought to be beyond the capabilities of machines. This will further increase the range of applications for Industrial robots and drive their adoption in a wider range of industries.

In conclusion, the Industrial robot is a transformative technology that is reshaping the landscape of manufacturing and automation. By increasing efficiency, improving quality, and enhancing safety, Industrial robots are playing a crucial role in the modernization of industry. As technology continues to advance, the capabilities of Industrial robots will only grow, opening up new possibilities for innovation and growth in the manufacturing sector.