The Comprehensive Guide to Hollow Rotating Platforms: Applications, Benefits, and Maintenance

Hollow rotating platforms are an integral part of various industrial and mechanical systems, providing a stable and reliable means of rotation for numerous applications. These platforms are designed to support heavy loads while allowing for precise and controlled rotation, making them indispensable in fields such as robotics, automation, and heavy machinery. This comprehensive guide delves into the world of hollow rotating platforms, exploring their applications, benefits, and maintenance practices to ensure optimal performance and longevity.

Applications of Hollow Rotating Platforms

Hollow rotating platforms are versatile components that find their way into a wide array of industries. Some of the most common applications include:

- Automotive Industry: They are used in assembly lines for the rotation of car parts, ensuring precision in the alignment and assembly of components.

- Aerospace: Hollow rotating platforms are crucial in the manufacturing and maintenance of aircraft, where high precision and load-bearing capabilities are required.

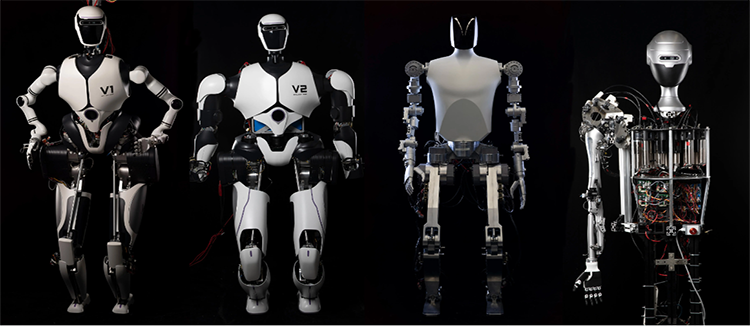

- Robotics: In robotic arms and manipulators, these platforms provide the necessary rotation for tasks such as welding, painting, and assembly.

- Medical Equipment: Hollow rotating platforms are used in medical imaging and diagnostic equipment, where precise movement is critical for accurate results.

Benefits of Hollow Rotating Platforms

The benefits of using hollow rotating platforms are manifold, and they contribute significantly to the efficiency and effectiveness of various operations:

- High Load Capacity: These platforms are engineered to handle substantial weights, making them suitable for heavy-duty applications.

- Precision and Accuracy: Hollow rotating platforms offer high precision in rotation, which is essential for tasks that require exact positioning.

- Durability: Made from robust materials, these platforms are designed to withstand the test of time and heavy use without compromising performance.

- Versatility: Their hollow design allows for the integration of various components, such as cables and pipes, making them adaptable to different setups.

- Efficiency: By enabling smooth and controlled rotation, hollow rotating platforms contribute to increased productivity and reduced downtime in industrial processes.

Maintenance of Hollow Rotating Platforms

To ensure that hollow rotating platforms continue to perform at their best, regular maintenance is crucial. Here are some key points to consider:

- Lubrication: Regularly lubricate the bearings and moving parts to reduce friction and prevent wear.

- Inspection: Periodic inspections can help identify any signs of wear or damage, allowing for timely repairs or replacements.

- Cleaning: Keep the platform clean to prevent debris from interfering with its operation and causing damage.

- Alignment: Ensure that the platform is properly aligned to avoid uneven wear and tear on the components.

- Replacement Parts: Keep spare parts on hand for quick replacements in case of component failure.

Conclusion

Hollow rotating platforms are a critical component in many industries, offering a combination of strength, precision, and versatility that is hard to match. By understanding their applications, benefits, and the importance of regular maintenance, users can maximize the efficiency and lifespan of these platforms. Investing in high-quality hollow rotating platforms is not just about immediate operational needs but also about ensuring long-term reliability and performance in any mechanical or industrial setup.