The Hollow Rotating Platform: A Pivotal Component in Precision Engineering and Robotics

The Hollow Rotating Platform, often referred to as the backbone of precision engineering and robotics, is a mechanical device that has revolutionized the way we approach complex rotational movements. This sophisticated component is designed to provide high-precision rotation around a central axis, allowing for seamless integration into various applications where accuracy and reliability are paramount.

A Hollow Rotating Platform is characterized by its hollow center, which enables the passage of cables, wires, or other components through it without obstructing the rotation. This feature is particularly beneficial in applications where space is limited, or where the rotation of the platform must not interfere with other moving parts or systems.

The platform's operation is based on a series of gears and bearings that ensure smooth and precise rotation. The engineering behind a Hollow Rotating Platform is meticulous, with each component designed to withstand high torque and maintain accuracy over extended periods of operation. This precision is crucial in industries such as aerospace, where even the slightest deviation can have significant consequences.

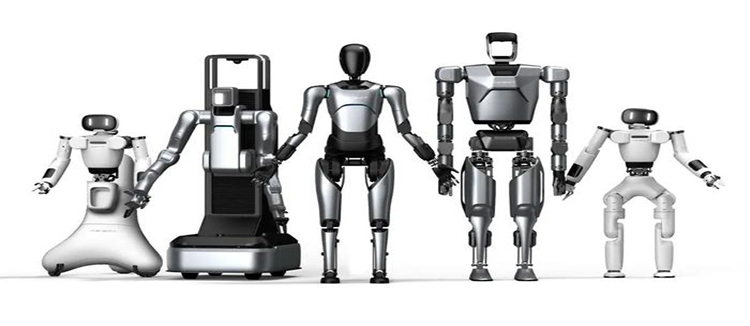

One of the key advantages of a Hollow Rotating Platform is its versatility. It can be used in a wide range of applications, from industrial automation to medical equipment. In robotics, for instance, a Hollow Rotating Platform can serve as a base for a robotic arm, allowing it to rotate and position tools or sensors with pinpoint accuracy. This capability is essential in tasks that require high precision, such as assembly work or surgery.

The Hollow Rotating Platform's design also lends itself well to customization. Manufacturers can tailor the platform to meet specific requirements, such as adjusting the size, load capacity, and rotation speed to fit the needs of the application. This adaptability is a significant factor in the platform's popularity across various sectors.

Maintenance and durability are also critical aspects of a Hollow Rotating Platform. High-quality materials and advanced manufacturing processes ensure that the platform can withstand the rigors of continuous use. Regular maintenance, such as lubrication and inspection of the bearings, is essential to prolong the life of the platform and maintain its performance.

In the realm of precision engineering, the Hollow Rotating Platform stands out as a critical component that enables the creation of advanced machinery and systems. Its ability to provide reliable and accurate rotation is unmatched, making it an indispensable tool in the engineer's arsenal.

As technology continues to advance, the Hollow Rotating Platform is expected to play an even more significant role in the development of new and innovative applications. Its potential for integration into cutting-edge systems is vast, and its impact on the fields of robotics and precision engineering is undeniable.