Understanding the Role and Benefits of Harmonic Reducer in Industrial Applications

When it comes to precision and efficiency in industrial machinery, the Harmonic Reducer stands out as a critical component. This sophisticated device is designed to reduce the speed of a rotating drive shaft while simultaneously increasing torque. Understanding the intricacies of the Harmonic Reducer is essential for engineers and technicians who seek to optimize the performance of their equipment. In this article, we will delve into the role of the Harmonic Reducer, its benefits, and its applications in various industries.

The Harmonic Reducer, also known as a harmonic drive or a wave generator, operates on the principle of elliptical gears. It consists of three main components: a flexible spline, a circular spline, and a wave generator. The flexible spline is an elliptical gear that meshes with the circular spline, which is a rigid gear. The wave generator, which is the driving component, deforms the flexible spline, causing it to rotate and transfer motion to the circular spline. This unique mechanism allows for a significant reduction in speed and an increase in torque, making the Harmonic Reducer an invaluable tool in many applications.

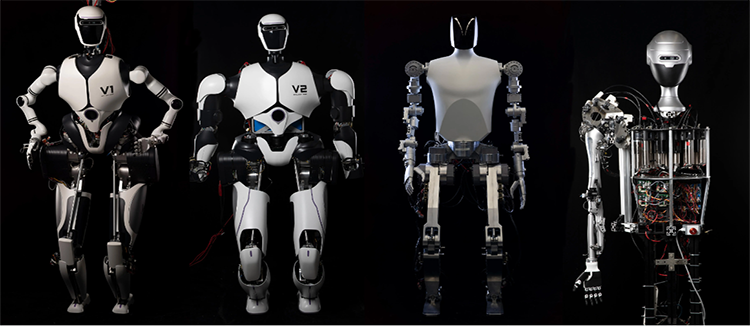

One of the primary benefits of using a Harmonic Reducer is its high torque density. Due to its compact design and the nature of its operation, it can deliver a high torque output relative to its size. This characteristic is particularly advantageous in applications where space is limited, such as in robotics, aerospace, and automotive industries. The ability to achieve high torque in a small package can lead to more efficient designs and reduced overall system weight.

Another significant advantage of the Harmonic Reducer is its precision. The elliptical gears ensure that the output shaft maintains a constant velocity ratio, which is crucial for applications requiring high precision and accuracy. This precision is essential in fields such as medical equipment, where the Harmonic Reducer can be found in devices such as surgical robots and imaging systems.

The Harmonic Reducer also boasts a high efficiency, often reaching up to 90% or more. This efficiency is due to the minimal friction between the gears and the smooth transfer of motion. High efficiency is particularly important in energy-intensive applications, where reducing energy consumption can lead to significant cost savings and environmental benefits.

In terms of applications, the Harmonic Reducer is used in a wide range of industries. In robotics, it is used to provide precise and controlled movements for arms and grippers. In aerospace, it is employed in satellite positioning systems and spacecraft attitude control. In the automotive industry, it can be found in electric and hybrid vehicles, where it helps to manage the high torque from electric motors. Additionally, in industrial automation, the Harmonic Reducer is used in conveyor systems, packaging machines, and other automated processes that require precise speed control and high torque.

Maintenance and reliability are also key factors when considering the use of a Harmonic Reducer. Due to its compact design and the minimal number of moving parts, the Harmonic Reducer requires less maintenance and has a longer service life compared to other types of reducers. This reliability is crucial in industries where downtime can be costly, such as in manufacturing and processing plants.

In conclusion, the Harmonic Reducer is a versatile and essential component in many industrial applications. Its ability to provide high torque density, precision, and efficiency in a compact package makes it an ideal choice for a wide range of uses. As technology continues to advance, the demand for Harmonic Reducers is likely to grow, further solidifying their importance in the world of engineering and design.