The Comprehensive Guide to Gas Electric Slip Rings: Applications, Benefits, and Maintenance

Gas electric slip rings are critical components in various industrial and technological applications, facilitating the transmission of electrical signals and power between stationary and rotating parts. This comprehensive guide delves into the world of gas electric slip rings, exploring their applications, benefits, and maintenance practices to ensure optimal performance and longevity.

What are Gas Electric Slip Rings?

Gas electric slip rings, also known as electrical slip rings or rotary joints, are devices that enable the transfer of electrical power and data signals across a rotating interface. They are commonly used in applications where continuous rotation is required, such as in robotics, aerospace, and renewable energy sectors. The primary function of these slip rings is to maintain a reliable connection between the rotating and stationary parts of a system, ensuring uninterrupted power and data transfer.

Applications of Gas Electric Slip Rings

The versatility of gas electric slip rings makes them indispensable in a wide range of industries. Some of the key applications include:

- Automotive Sector: In electric vehicles, slip rings are used to transfer power and data between the stationary battery pack and the rotating electric motor.

- Renewable Energy: Wind turbines and solar trackers rely on slip rings to maintain communication and power supply between the rotating blades or panels and the stationary control systems.

- Aerospace: In helicopters and drones, slip rings are essential for transmitting signals and power to rotating components such as rotors and propellers.

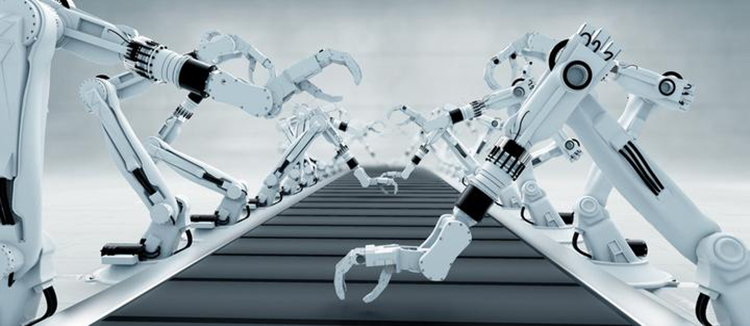

- Industrial Robotics: Slip rings are used in robotic arms to ensure continuous power and data flow as the arm rotates and moves.

Benefits of Gas Electric Slip Rings

The benefits of using gas electric slip rings are numerous and contribute significantly to the efficiency and reliability of various systems:

- Reliability: Slip rings provide a robust connection that can withstand harsh environments and continuous rotation without signal degradation.

- Durability: High-quality slip rings are designed to last, reducing the need for frequent replacements and minimizing downtime.

- Flexibility: They offer the flexibility to transmit both power and data, catering to the needs of complex systems that require multiple signal types.

- Efficiency: By maintaining a continuous connection, slip rings help to reduce energy loss and improve overall system efficiency.

Maintenance of Gas Electric Slip Rings

Proper maintenance is crucial for the longevity and performance of gas electric slip rings. Here are some key maintenance practices:

- Regular Inspection: Regularly inspect the slip ring for wear and tear, ensuring that the contacts are clean and free from debris.

- Lubrication: Apply appropriate lubricants to reduce friction and prevent wear, especially in high-speed applications.

- Replacement of Contacts: Replace worn contacts promptly to maintain optimal signal and power transfer.

- Environmental Control: Keep the slip ring clean and free from dust and moisture, which can cause corrosion and signal interference.

Conclusion

Gas electric slip rings play a pivotal role in modern technology, ensuring seamless communication and power transfer in rotating systems. By understanding their applications, benefits, and maintenance requirements, users can maximize the efficiency and reliability of their equipment. Investing in high-quality slip rings and adhering to proper maintenance practices will ensure that these critical components continue to perform at their best.